Every year the world produces an estimated 11.2 billion tonnes of solid waste worldwide.[1]

A significant proportion of the world’s waste is e-waste; waste which results from discarded electronic devices. Per capita annual e-waste generated globally has increased from 5.3 to 7.3 kilogrammes. In total, this amounts to 50 million tonnes of e-waste per year, which weighs more than all the commercial airliners ever made. If current trends continue, global e-waste production will reach 120 million tonnes.[2]

Only 17% of e-waste is formally recycled.[3] In some poorer nations,[4] clandestine e-waste disposal is a very large industry. The International Labour Organization estimates up to 100,000 people work in the informal e-waste sector in Nigeria. Most of the e-waste exported to these companies goes through a ‘quasi’ legal process, often from economic regions such as the EU, and makes up a ‘vast and lucrative’ criminal industry according to Interpol.[5]

E-waste that is informally recycled is often burned. In this image, in Agbogbloshie, Ghana, workers burn wires from electronic devices to recover copper and other metals. Burning e-waste results in significant environmental impacts. The most obvious impact is from carbon emissions; 4.25% of greenhouse emissions result from e-waste that is not recycled.[6]

In addition to the carbon emissions, there are significant health costs to workers at informal e-waste centres. In studies, workers at the Agbogbloshie scrapyard have shown elevated levels of arsenic and other dangerous trace elements in their systems.[7] Children often work at these sites, who are known to be much more sensitive to chemical health hazards than adults.[8]

E-waste is also highly wasteful, in terms of resources and precious metals. There is 100 times more gold in a tonne of e-waste than in a tonne of gold ore. The UN estimates that 7% of the world’s gold is currently in e-waste.[9] In recent months, there have been breakthroughs in salvaging gold from e-waste,[10] but these are only possible at formal recycling centres with cutting-edge technology. At informal centres, where 80% of e-waste goes, most of the gold is not extracted.

The e-waste crisis needs strong action. An initially seeming appropriate solution would be to increase recycle rates above 20%. But although the 17% formal recycle rate for e-waste is shameful, recycling e-waste is not enough to solve the e-waste crisis.[11]

Recycling is not enough; Re-use is essential.

A seemingly easy solution to the e-waste problem is to improve recycle rates for e-waste. In fact, this is only the very beginning of solving the problem. Microsoft says that 78% of a Surface’s carbon footprint is from manufacturing.[12] A report from 2018 claims that 85-95% of a phone’s annual carbon footprint results from its manufacturing.[13] The salvaging and re-production process, therefore, still results in significant carbon emissions.

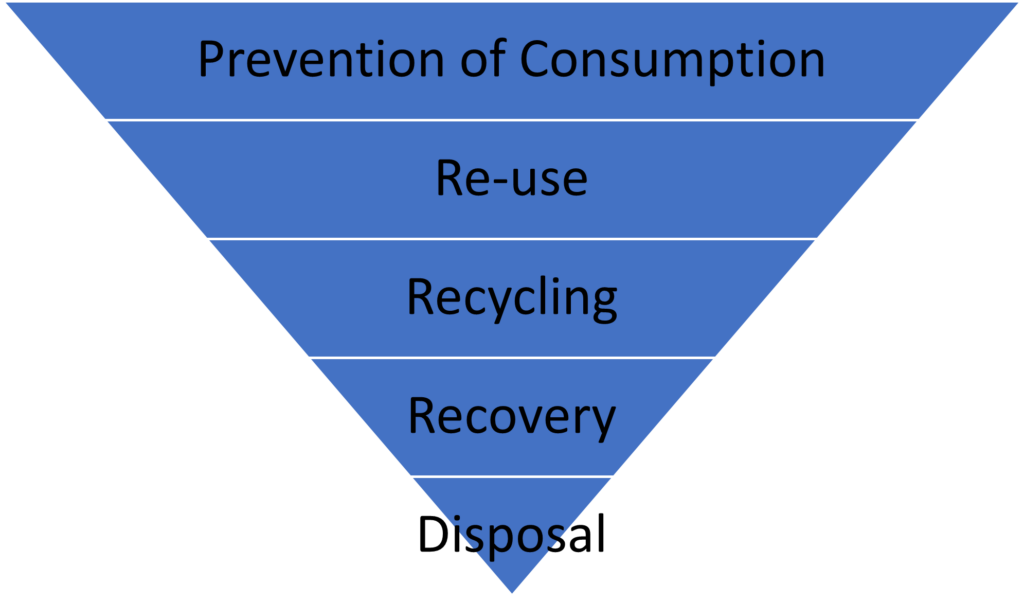

In the EU waste hierarchy, recycling is on the lower end for ways to combat carbon emissions and environmental damage. Avoiding consumption entirely is the highest strategy in the hierarchy. But with global population expected to continue rising, increased demand for electronics will likely continue.[14]

EU Waste Hierarchy[16]

The next best strategy, above recycling, is reuse. Reuse is where a device is transferred to a second owner, often after being refurbished, rather than recycled. Recent studies show that sustainable waste initiatives still predominantly focus on recycling.[15] To solve the e-waste crisis, we need to create an economy which prioritises re-use.

The Circular Economy

A terrarium is a glass container which contains soil, plants, and sometimes small animals. A terrarium is a miniature ecosystem; it has a small-scale water cycle, where the water evaporates and condenses. Because of the water cycle, the life within the terrarium can exist in its small chamber (if it has sunlight) in perpetuity.

A terrarium does not need constant feeding from water and fertiliser. Due to It is cyclical re-use of water, it is far less resource intensive than a regular household plant. Whereas a household plant needs water once a week, a terrarium re-uses the water it already has.

A research field known as industrial ecology makes extensive analogy between industrial systems and ecosystems. An industrial system is the set of processes and interactions that support the creation and delivery of products and services of a certain type. An ecosystem is a biological community of interacting organisms and their physical environment. The analogy between industrial systems and ecosystems primarily makes use of their common need for inputs for their systems to perpetuate. For example, a forest requires sunlight and water to perpetuate, and the fishing industry requires fuel and materials to be made into fishing implements.

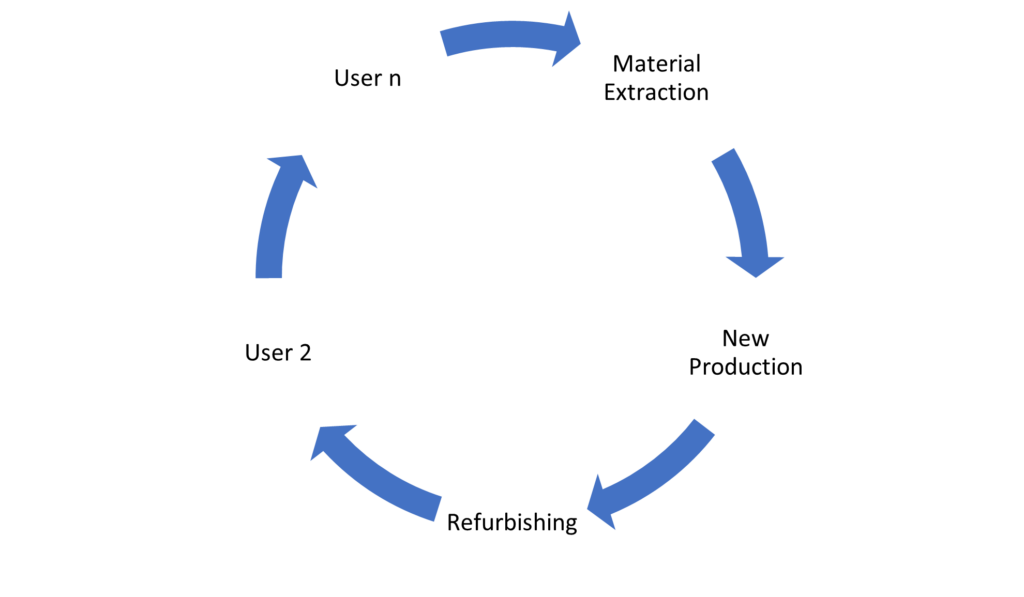

The kind of industrial system that is analogous to a terrarium is called a ‘circular economy.’ Just how a terrarium re-uses its water, a circular economy re-uses its inputs. Specific to the IT industry, a circular economy prioritises re-use, with recycling second. This is because recycling allows for more inputs to leave the system than re-use. A diagram for effectively decreasing e-waste and greenhouse gas emissions from IT looks as follows:

Circular Economy for IT

SMART’s contribution to the Circular Economy

A terrarium is a circular eco-system because it has infrastructure in place to avoid loss of resources. Namely, this infrastructure is the glass container that surrounds the life in the terrarium. The glass ensures that water that evaporates from the life in the terrarium condenses on the glass, sinks to the soil, and is re-used. Just like the terrarium, to achieve an IT circular economy we require infrastructure.

Innovative businesses and organisations are developing services that build an infrastructure for an IT circular economy. There are many examples. BackMarket is an online marketplace for re-used IT, which promotes re-use by providing a forum for exchange of used goods. The Ellen MacArthur Foundation conducts research, provides resources, and hosts a cross-disciplinary community to encourage the proliferation of information about circular economy initiatives. FairPhone designs its phones to prioritise ease of refurbishing, to avoid unnecessary new production by extending product life before recycling. Each organisation, in its own way, provides infrastructure for the IT circular economy by improving ease of re-use.

SMART, our tool for injecting Windows license keys, also provides infrastructure for the IT circular economy. When a computer transfers ownership, the Windows license on the device is not automatically transferred. Therefore, for the devices to legally contain a Windows operating system, a Windows license key must be injected to the device. SMART does exactly this; it provides the easiest way to inject a Windows license to a refurbished PC.

Windows licenses for refurbished PCs are also less expensive than Windows licenses for new PCs, which provides a further economic incentive to refurbish.

To respond to the climate and e-waste crises, we must transition to a circular economy. In our own way, with SMART we hope to create infrastructure which hastens this transition.

Sign up to SMART today to lead the transition to a circular economy.

References

[1] https://www.unep.org/explore-topics/resource-efficiency/what-we-do/cities/solid-waste-management

[2] https://www.unep.org/news-and-stories/press-release/un-report-time-seize-opportunity-tackle-challenge-e-waste

[3] United Nations University, Baldé, C.P., et al., The Global E-waste Monitor 2017: Quantities, Flows, and Resources (2017)

[4] https://ourworld.unu.edu/en/toxic-e-waste-dumped-in-poor-nations-says-united-nations

[5] Interpol Electronic Waste and Organized Crime Assessing the Links 2009.

[6] https://cop23.unfccc.int/climate-action/momentum-for-change/lighthouse-activities/e-waste-from-toxic-to-green

[7] Asante et al. Multi-trace element levels and arsenic speciation in urine of e-waste recycling workers from Agbogbloshie, Accra in Ghana. in Science of the Total Environment 2012 doi:10.1016/j.scitotenv.2012.02.072

[8] https://pubmed.ncbi.nlm.nih.gov/10915586/

[9] https://www.unep.org/news-and-stories/press-release/un-report-time-seize-opportunity-tackle-challenge-e-waste

[10] https://www.bbc.co.uk/newsround/58971402

[11] https://www.digitaltrends.com/computing/why-recycling-isnt-enough-to-solve-e-waste-crisis/

[12] https://devblogs.microsoft.com/sustainable-software/examining-the-carbon-footprint-of-devices/

[13] https://www.anthropocenemagazine.org/2018/04/the-energy-hogging-dark-side-of-smartphones/

[14] https://www.un.org/development/desa/en/news/population/world-population-prospects-2019.html

[15] https://environment.ec.europa.eu/topics/waste-and-recycling/waste-framework-directive_en

[16] Allwood, J. M. 2014. Squaring the circular economy: The role of re-cycling within a hierarchy of material management strategies. In Handbook of recycling: State-of-the-art for practitioners, analysts,

and scientists, edited by M. Reuter and E. Worrell; Potting, et al. 2017. Circular economy: Measuring innovation in product chains. Policy report 2544.